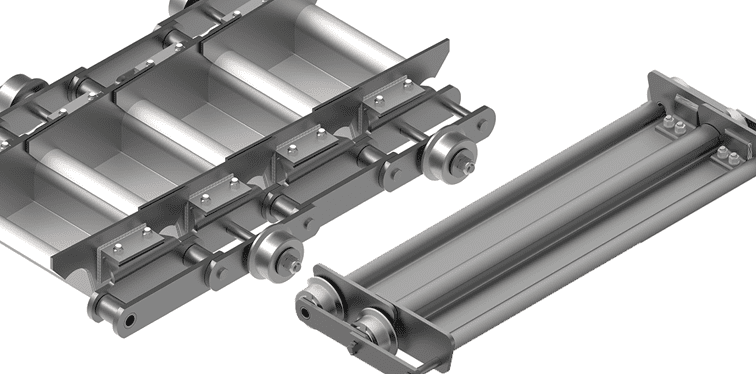

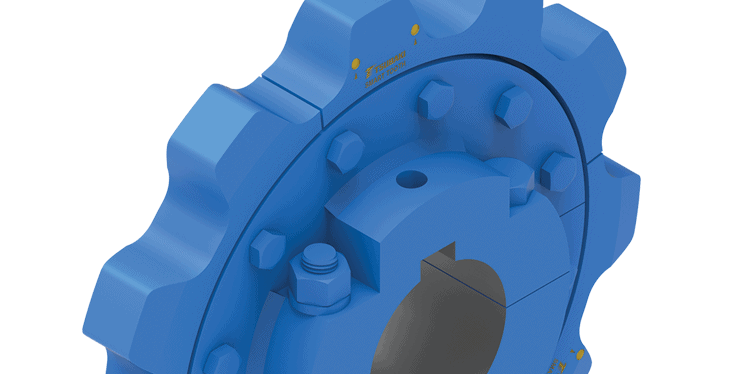

With experienced engineers who understand the changing demands of the market, Tsubaki of Canada proudly features heavy-duty engineered chain, designed to withstand rigorous operating conditions across a range of applications. Greater reliability, productivity and wear life are attributes associated with Tsubaki’s engineered class product.

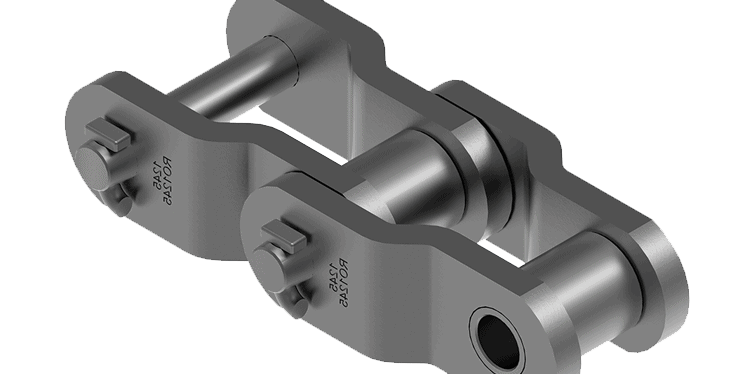

Tsubaki offers a full lineup of engineering class chain, including Drive, Roller Conveyor, Steel Bushed, Welded Steel, Drop Forged, Bar and Pin and more. For additional information, please select a product group below.

Tsubaki chain is found in diverse applications including food packaging, forklift trucks, oilfield drilling, motorcycles, and any other application that requires durable conveyors and maximum power transfer in a compact space.

Our Engineering Class Chain Lines

Tsubaki Chain is Found in Diverse Applications including food packaging, forklift trucks, oilfield drilling, motorcycles, and any other application that requires durable conveyors and maximum power transfer in a compact space.