Tsubaki Pin Gear Drive Units (PDU) are a new type of transmission unit to replace gears and racks. Consisting of a pin wheel and rack, and a gear with a unique tooth profile, Pin Gear Drive Units offer limitless design possibilities for rotating and linear drives.

Tsubaki Pin Gear Drive Units use a segmented system for easy installation, while rough mounting precision is allowed. The pin gears are designed as modules with some leeway. The right balance between pin wheels and racks allow them to generate large transmission torque.

Furthermore the system can be used on large equipment. By simply increasing the number of wheel segments you can enable use on large equipment drives. Large size Pin Gear Drive Units are perfect for steel industry applications. They outperform large gears in terms of cost and tangential force.

Tsubaki Pin Gear Drive Units are also available in a complete line-up of stainless steel series (S Series) that can be used in corrosive environments, such as in contact with water, acids, or alkalis.

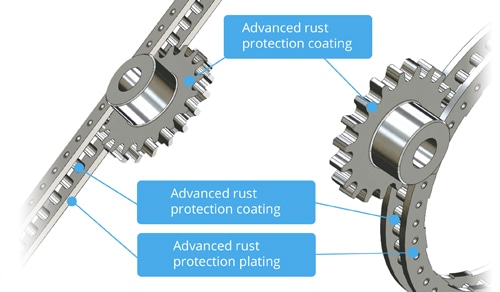

The Advanced Rust Protection Series offers improved corrosion resistance thanks to a special surface treatment. Each part has been optimally treated for advanced rust protection in severe environments such as outdoors, around water, or in coastal areas.

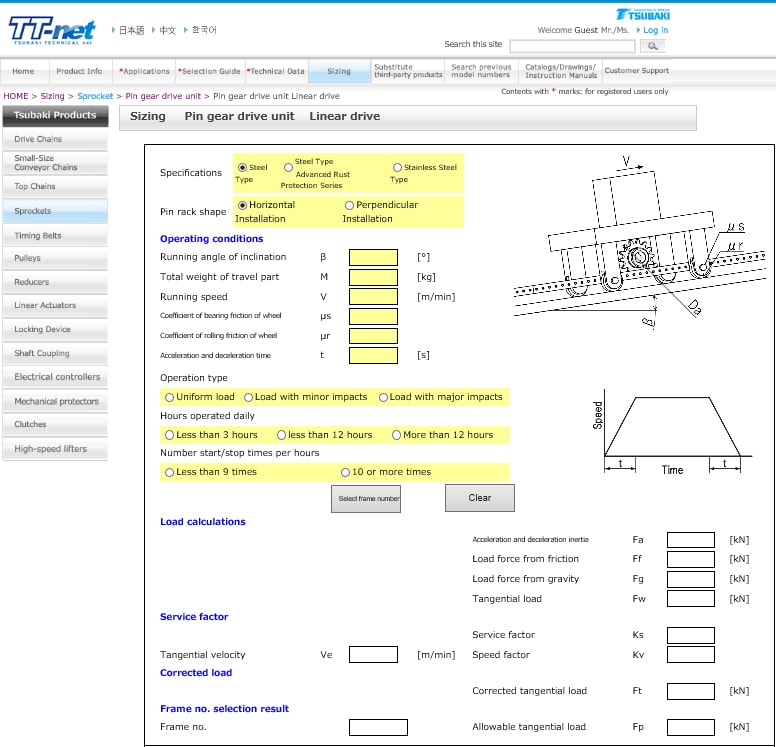

TSUBAKI TT-NET

For easy calculation of Tsubaki Pin Gear Drive Unit load you can visit TT-net (Tsubaki Technical net) and use our Pin Gear Drive Selection Service.

Read more about the Tsubaki Pin Gear Drive Unit line-up here.