Processing of cement and aggregate materials is especially challenging for equipment and components. Not only is the equipment commonly used in outdoor settings where extreme weather conditions can be a challenge, but it is also directly exposed to abrasive materials that can accelerate wear while lubrication is often unfeasible and sometimes counterproductive.

Processing of cement and aggregate materials is especially challenging for equipment and components. Not only is the equipment commonly used in outdoor settings where extreme weather conditions can be a challenge, but it is also directly exposed to abrasive materials that can accelerate wear while lubrication is often unfeasible and sometimes counterproductive.

Exposure to weather, dust, abrasive contaminants, and little or no lubrication can lead to corrosion, accelerated wear, and unforeseen breakages, resulting in unexpected downtime and replacements of worn or broken parts. Tsubaki offers high-performance roller chains and engineering class chains with improved durability and other special features for bucket elevators, large-sized mixers, conveyance systems, and high-impact chain drive systems to produce reliable performance under these most demanding conditions.

Let’s look at some of the ways Tsubaki products can offer safe and reliable operation under such challenging conditions.

Case Studies

Roller Chains: Long Wear Life in Tough Conditions

Production and application of cement and asphalt as well as processing of the aggregate materials are typically associated with large pitch roller chains employed on mixers, drive sections of the conveyance systems, and highly specialized OEM machines.

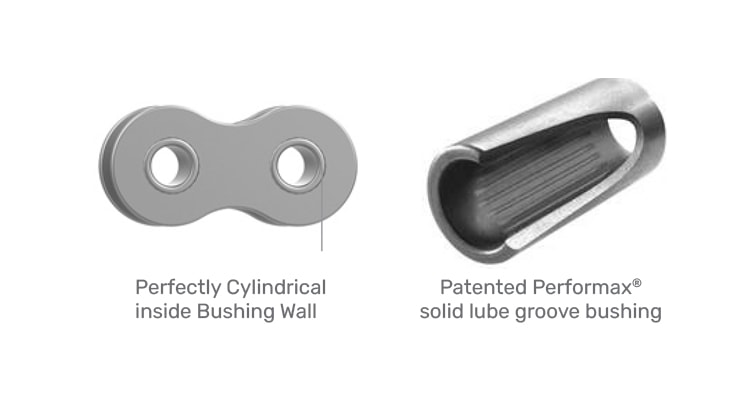

- PerforMax® Bushings: Only Tsubaki premium roller chain has the proprietary PerforMax® Solid Lube Groove Bushings on sizes 80-140. These highly engineered bushings double the wear characteristics compared to conventional roller chain especially for applications where effective lubrication cannot be maintained.

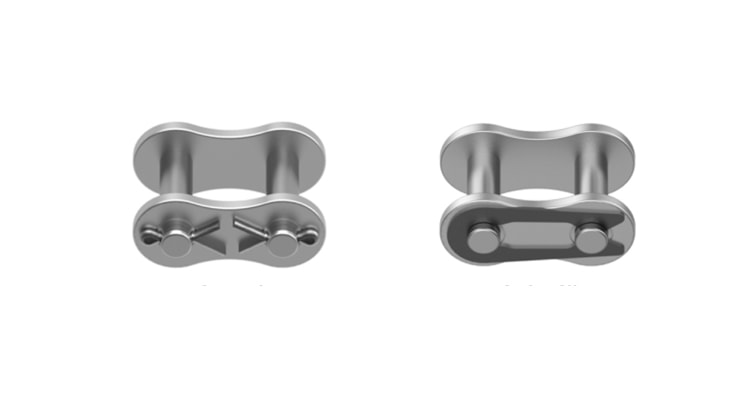

- Ring Coined Connecting Links: Use of a standard connecting link in chain reduces its strength rating. Tsubaki’s connecting links with Ring Coined plates are as strong as the base chain. Our patented ring-coining process increases fatigue strength and durability. With this advanced connecting link, the chain can offer longer service life and superior performance for your application.

- High Performance Titan® Series: Tsubaki Titan® chain is specifically developed for better performance in the high-speed, abrasive applications, where the pin surface with lower friction and higher hardness is designed to reduce wear, hence improving chain wear characteristics. In addition, special coatings on the side plates provide better corrosion resistance in outdoor settings.

- Neptune® and Other Coatings: Tsubaki has developed a variety of special coatings including Neptune® Series to help carbon steel chain resist outdoor conditions. These coatings deliver exceptional corrosion resistance in applications exposed to water, high humidity, some chemicals, and other conditions.

- Super and Super H Series: The reliability of equipment is closely related to a chain’s ability to withstand constantly changing operating loads where fatigue strength is the key focus. When the equipment experiences the extreme loads, Tsubaki Super or Super H Series roller chains with wider-waist, thicker link plates, ball-drifted pitch holes, and through-hardened pins are options that provide greater shock resistance and higher maximum allowable loads, improving the reliability of equipment operation.

- Tsubaki Premium Alloys: Combined with optimized heat treatment, Tsubaki premium materials give standard chain an advantage in dirty, abrasive environments. In the most difficult applications, Tsubaki Titan® Series offers even higher wear resistance, which is critical in the environment where the abrasives (fine grit and dust) contaminate lubricant, resulting in buildup and accelerated wear on chain.

- Cut-to-Length Service: Roller chain is typically stocked and supplied as 10-ft boxes or on reels. This often requires the user to cut chain before installing on the equipment. Cutting heavy-duty large pitch roller chain in outdoor settings is a big challenge. Tsubaki offers cut-to-length service for those users – chain strands will be supplied in specific length as specified.

PERFORMAX® BUSHINGS

PERFORMAX® BUSHINGS

RING COINED CONNECTING

RING COINED CONNECTING

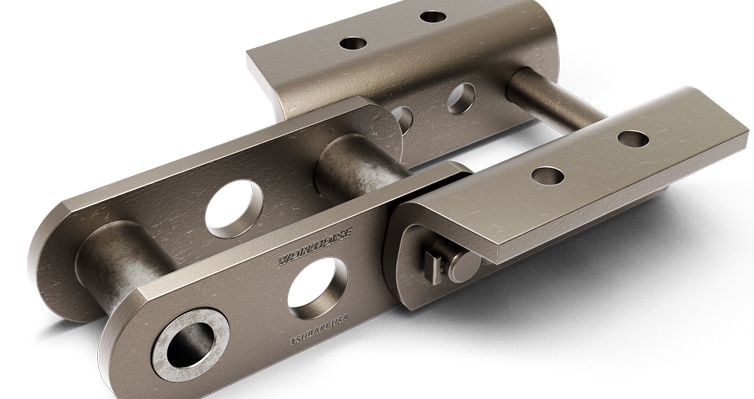

Engineering Class Chains: Excelling in Demanding Environments

Often used in bulk material handing applications such as bucket elevators, stackers, feeders, and drag conveyors, Tsubaki’s heavy-duty engineered chains, sprockets and access doors are designed to withstand the demanding conditions of the cement and aggregate materials industry.

- Workhorse® Series: Tsubaki’s Workhorse Series Chain is manufactured with premium, high strength, heat-treated steels, allowing for superior wear resistance and renowned reliability. High interference press fits offer enhanced stability and exceptional fatigue resistance. Premium upgrades include TitanXL® plated pins and bushings, as well as various types of proprietary joint seals that help protect against abrasive contaminants.

- One-Touch Inspection Doors®: Complete with a three-part patented design, these doors are easy and convenient to install, are lockable and provide a sealed interface to inhibit the flow of dust and debris in and/or out of the housing. For a simple and cost-effective option, Tsubaki’s One-Touch Inspections Doors® are a durable, worthwhile investment. Standard sizes are normally stocked for quick shipment. Custom sizes are available upon request.

Sprockets: Powering Your System

You rely on sprockets to drive your critical equipment like bucket elevator chains, feeder chains, pan conveyor chains and reclaimer chains. A worn-down sprocket can lead to lead to tension loss, slippage, or a jumped chain, putting a stop to your entire operation. Tsubaki specializes in designing and manufacturing high-quality sprockets that make it easier to detect signs of wear, so you can schedule replacement before critical failure occurs.

- Smart Tooth® Sprocket: Strategically placed wear indicator pins on one or more sprocket teeth provide a visual indication that a sprocket is either still within the allowable wear tolerance, or that it needs to be replaced.

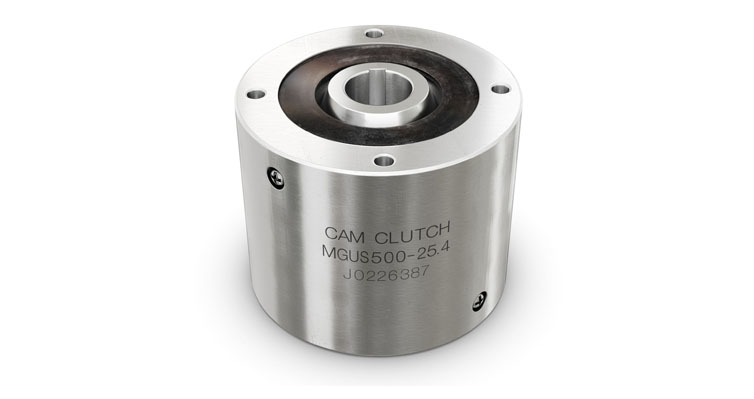

Backstops & Clutches: Ensuring Safe, Uninterrupted Operations

When conveyors or bucket elevators roll backwards unexpectedly, it can pose a serious safety risk to workers and result in an expensive cleanup. Keeping backstops & clutches well lubricated is essential to maximizing their performance day in and day out.

Tsubaki Backstops have special robust seal designs with grease lubrication for extended maintenance cycles and long lifetimes. The seal design prevents outside contamination from affecting the lubrication of the backstops. It also lowers the amount of required maintenance, reducing the need to monitor oil levels, refill the backstop, or measure the amount of moisture in the lubricant.

- BS-F Series: Designed to be a simple, drop-in replacement for most major competitive backstops, the Tsubaki BS-F Series ensures efficient and dependable operation in cement plants. It uses an original cam design that has a larger profile and higher torque rating than other leading competitors. Utilizing Non-rollover cams, even if an unexpectedly large reverse torque occurs, the BS-F will not roll over, preventing a conveyor from reversing.

- BRUS Series: The BRUS Series provides non-rollover protection and “lift-off” operation to achieve a low operating temperature and long life. The flexible design of the BRUS torque arm also allows for re-use during regular maintenance and replacement.

Tsubaki clutches have built-in couplings that can be used to ensure a backup power source for rotating kiln or clinker drives. The overrunning clutch couplings allow for an automatic switch from a primary to a secondary power source once the secondary power source is up and running, ensuring uninterrupted operations in the event of a power failure.

- MGUS Series: Depending on application requirements, the MGUS Series can be used in overrunning, indexing, or backstopping applications and is the most commonly used clutch style in clutch coupling applications. The MGUS Series ships pre-lubricated with a thin layer of rust-prevention oil.

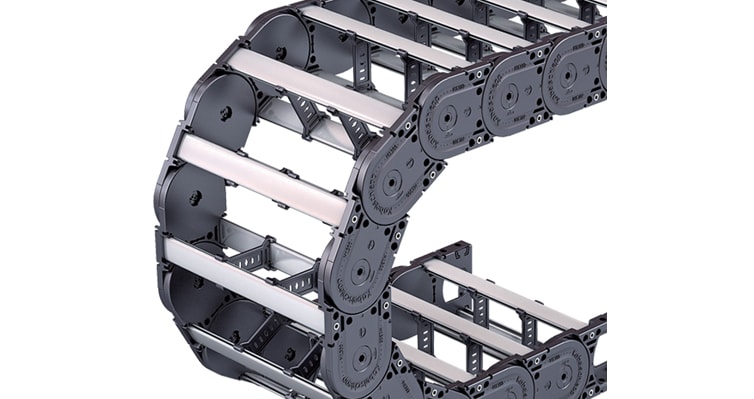

Tsubaki-KabelSchlepp® Cable Carriers: Maximum Protection for Cables

Choosing the right type of cable carrier can help you protect your cables in extendable conveyor systems, ensuring that cables do not get damaged when the conveyor is retracted for transport.

Tsubaki-KabelSchlepp® offers a full selection of materials – including steel and stainless steel – to provide the highest level of protection for cables and hoses in these applications. Tsubaki-KabelSchlepp® Cable Carriers also offer space-saving benefits when compared to large festoon systems.

- Vario-Line: The Vario-Line features a large selection of horizontal crossbar options, allowing you to customize your crossbar design to ensure minimal cable wear. The carrier also features a sturdy link plate design and an encapsulated, dirt-resistant stroke system that can help maximize wear life.

- UNIFLEX Advanced Series: The UNIFLEX Advanced Series has a robust link-pin design that provides exceptional strength and enables the track to achieve long self-supporting lengths. The dividers can be locked into position to Ensure no movement, even if the cable track is side mounted.