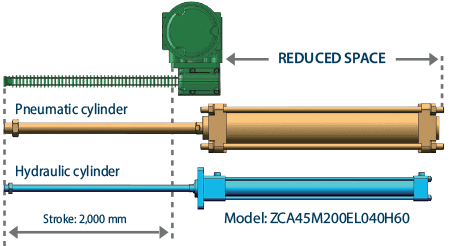

THE NEXT GENERATION OF COMPACT, HIGH-SPEED LINEAR ACTUATORS

THE NEXT GENERATION OF COMPACT, HIGH-SPEED LINEAR ACTUATORS

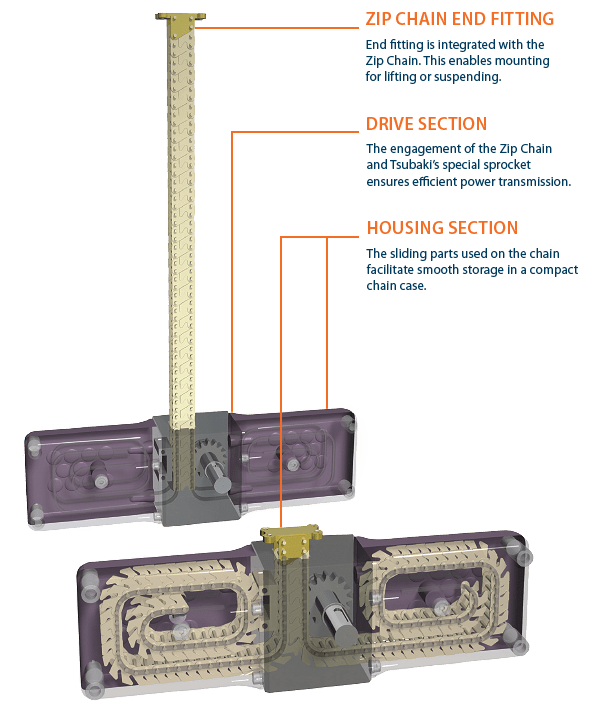

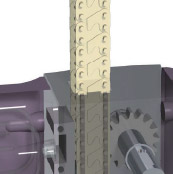

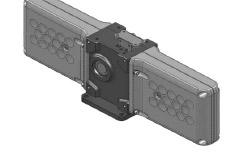

The patented Tsubaki Zip Chain Actuator® (ZCA) is the solution to your linear actuator application problems. The ZCA utilizes 100+ years of Tsubaki Roller Chain manufacturing expertise to create a linear actuator that “zips” together chain segments, creating a rigid actuating arm that offers high speed, multi-point stopping, efficient operation, and long life — all in a compact footprint.

APPLICATIONS

HS High SpeedHF High FrequencyC CompactHP High PrecisionE Economical

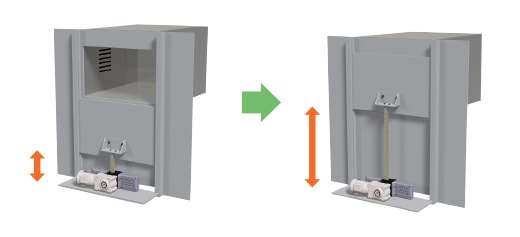

COMPACT DESIGN IDEAL FOR LOW HEIGHT APPLICATION

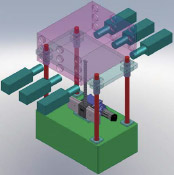

The compact structure of the ZIP CHAIN ACTUATOR® enables various installation options — including lifting, horizontal, and suspending installation. Use for a wide range of applications requiring linear operation.

Click the different application types below.

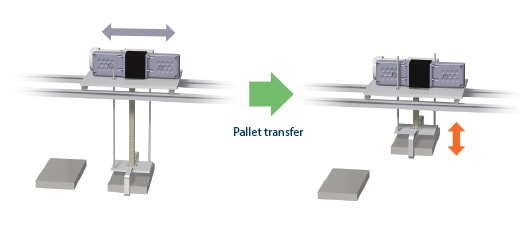

- Pallet Transfer Device

Pallet Transfer Device

HSHFC

Workpieces are raised and lowered for transferring, using an arm powered by the Zip Chain Actuator.

BENEFIT:

- Can be installed in the small space on the ceiling side

- Reduces the cycle time for conveyance by allowing for lifting at high speed

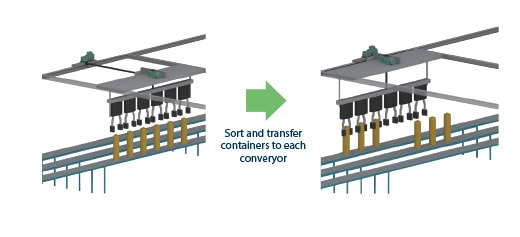

- Container Sorting Equipment

Container Sorting Equipment

HSC

Zip Chain Actuators can be used to move traversers horizontally and to raise or lower chucking units vertically.

BENEFIT:

- Horizontal and suspending installation are possible without protruding parts, enabling a lower height layout

- Accurate multi-point stopping even with horizontal transfers

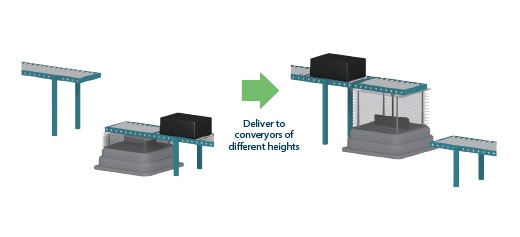

- AGV (Automated Guided Vehicle)

AGV (Automated Guided Vehicle)

HPC

Workpieces are transferred between conveyors at different heights using the Zip Chain Actuator mounted on AGV.

BENEFIT:

- Lift unit can be accommodated compactly in the AGV

- Height can be adjusted according to the conveyor height of the next process

- Furnace Door

Furnace Door

HSCE

Zip Chain Actuators can be used to push up and close furnace doors.

BENEFIT:

- Can be installed without protruding from equipment

- Higher speed operation prevents temperatures inside the furnace from changing

MODEL

SECTION

ARRANGEMENT

Size

- 25

- 35

- 45

Drive Section

- NWith No Drive Section

- MWith Integrated Hypoid Gear Motor*

- KWith Integrate TERVO Hypoid Reducer for Servo Motors*

Stroke

| Sizes | 25 | 35 | 45 | |||||

| Code | 020 | 050 | 050 | 075 | 100 | 100 | 150 | 200 |

| Allowable Stroke (mm) | 300 | 500 | 500 | 750 | 1000 | 1000 | 1500 | 2000 |

Mounting

| E | D* | ||

| Lifting Installation | Horizontal Installation | Suspending Installation (MTO) | |

|

|

|

|

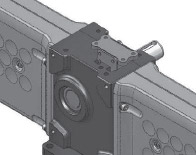

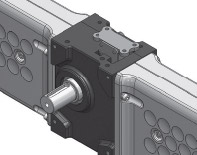

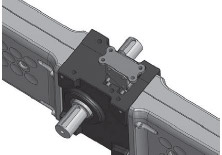

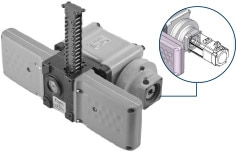

Shaft Arrangement

| L: Input shaft | R: Input shaft on opposite side | T: Dual Input shaft* |

|

|

|

Options

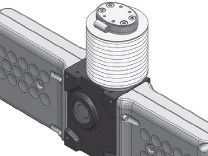

| Bellows* |

| J1: For lifting, suspending | J2: For horizontal |

|

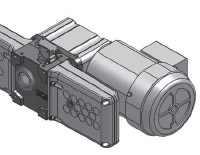

Drive Section

| M | K |

| With Integrated Hypoid Gear Motor* | With Integrated TERVO Hypoid Reducer for Servo Motors* |

|

|

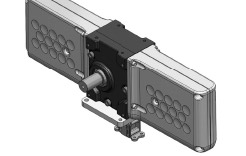

Attachable Options

| Upper Mounting Base | Lower Mounting Base |

|

|

Click the different characteristics and specifications to learn more.

- CHARACTERISTICS (WITHOUT BELLOWS)

Model Allowable stroke*1 Allowable thrust*2 Input shaft Maximum speed Zip Chain travel distance per input shaft rotation Approximate mass Allowable torque Allowable OHL Thrust direction Input shaft rotation Input shaft Standard/reverse shaft Input shaft Dual shafts Suspending Installation mm N {kgf} N•m {kgf•m} N {kgf} mm/sec (r/min) mm kg ZCA25N 030 300 400 {40.8} 9.41 {0.96} 638 {65} 1000 630 95.3 1.9 2.0 2.5 050 500 300 {33.6} 2.5 2.6 3.1 ZCA35N 050 500 1000 {102} 34.7 {3.53} 946 {96.4} 1000 420 142.9 5.1 5.5 6.0 075 750 6.5 7.0 7.5 100 1000 600 {61.2} 7.5 8.0 8.5 ZCA45N 100 1000 2000 {204} 116.6 {11.9} 2065 {210.5} 500 125 240 21 21 22 150 1500 25 25 27 200 2000 1200 {122.5} 30 30 31 - CHARACTERISTICS (WITH BELLOWS)

Model Allowable stroke*1 Allowable thrust*2 Input shaft Maximum speed Zip Chain travel distance per input shaft rotation Approximate mass Allowable torque Allowable OHL Thrust direction Input shaft rotation Input shaft Standard/reverse shaft Input shaft Dual shafts Suspending Installation mm N {kgf} N•m {kgf•m} N {kgf} mm/sec (r/min) mm kg ZCA25N 030 300 400 {40.8} 9.41 {0.96} 638 {65} 1000 630 95.3 2.5 2.6 3.1 050 500 300 {30.6} 3.1 3.2 3.7 ZCA35N 050 500 1000 {102} 34.7 {3.53} 946 {96.4} 1000 420 142.9 5.5 6.0 6.5 075 750 7.0 7.5 8.0 100 1000 431 {44} 8.0 8.5 9.0 ZCA45N 100 1000 2000 {204} 116.6 {11.9} 2065 {210.5} 500 125 240 22 22 23 150 1500 27 27 28 200 2000 900 {91.8} 32 32 33 - SPECIFICATIONS AND ENVIRONMENTAL REQUIREMENTS

ZCA main unit ZCA25N ZCA35N ZCA45N Drive section Material Forged steel Coating Color Black, Munsell N2.0 equivalent Housing section Material Polyacetal Iron Coating Color Purple grey Munsell 0.8P6.3/3.0 equivalent (molded) Black, Munsell N2.0 equivalent Chain Material Iron Lubricant Shell Alvania EP Grease 2 [Showa Shell Sekiyu K. K.] * This grease is applied before shipment. Environmental requirements Operating temperature 0 to 60°C Relative humidity 85% or less (no condensation) Ambient atmosphere Typical rain-free indoor environment with dust levels kept at a general factory level. Installation direction ZCA can be installed with any direction, be sure to mount a linear guide in the direction of travel. A mounting base is required to suspending installation.