Keep your system on the cutting edge with Tsubaki of Canada sprockets, and discover the difference quality makes. Tsubaki sprockets are manufactured from top-grade, heat treated steel to withstand heavy shock loading, resist abrasion, and provide long service life. Alloy and stainless steel sprockets are also available for extra corrosion resistance and food-grade applications.

For more information about our sprockets, please select a category below

Precision Manufacturing at our ISO-Registered Facilities ensures that every Tsubaki sprocket stands up to critical design specifications and meets the highest quality standards. You get long service life and reliable performance, turn after turn, time after time.

Click here to find out about our new SMART TOOTH® sprockets with Patented Wear Indicator Technology and how they may work for your application.

ABOUT SPROCKETS

A sprocket is a rotating mechanical wheel with teeth that engage with roller or conveyor chains to facilitate their movement in a variety of applications and equipment. As the sprocket rotates around a central shaft, the specially designed teeth engage the gaps in the chain to pull it with a secure grip regardless of whether it is in dirty or oily environments. Although they may resemble gears, sprockets are designed solely to work with chain and not with other sprockets or gears.

Tsubaki specializes in high quality drive and conveyance components, power transmission parts, and custom designed products. The integrity and performance of your transmission system relies on the suitability of your sprockets, and our team can help you find the perfect solution.

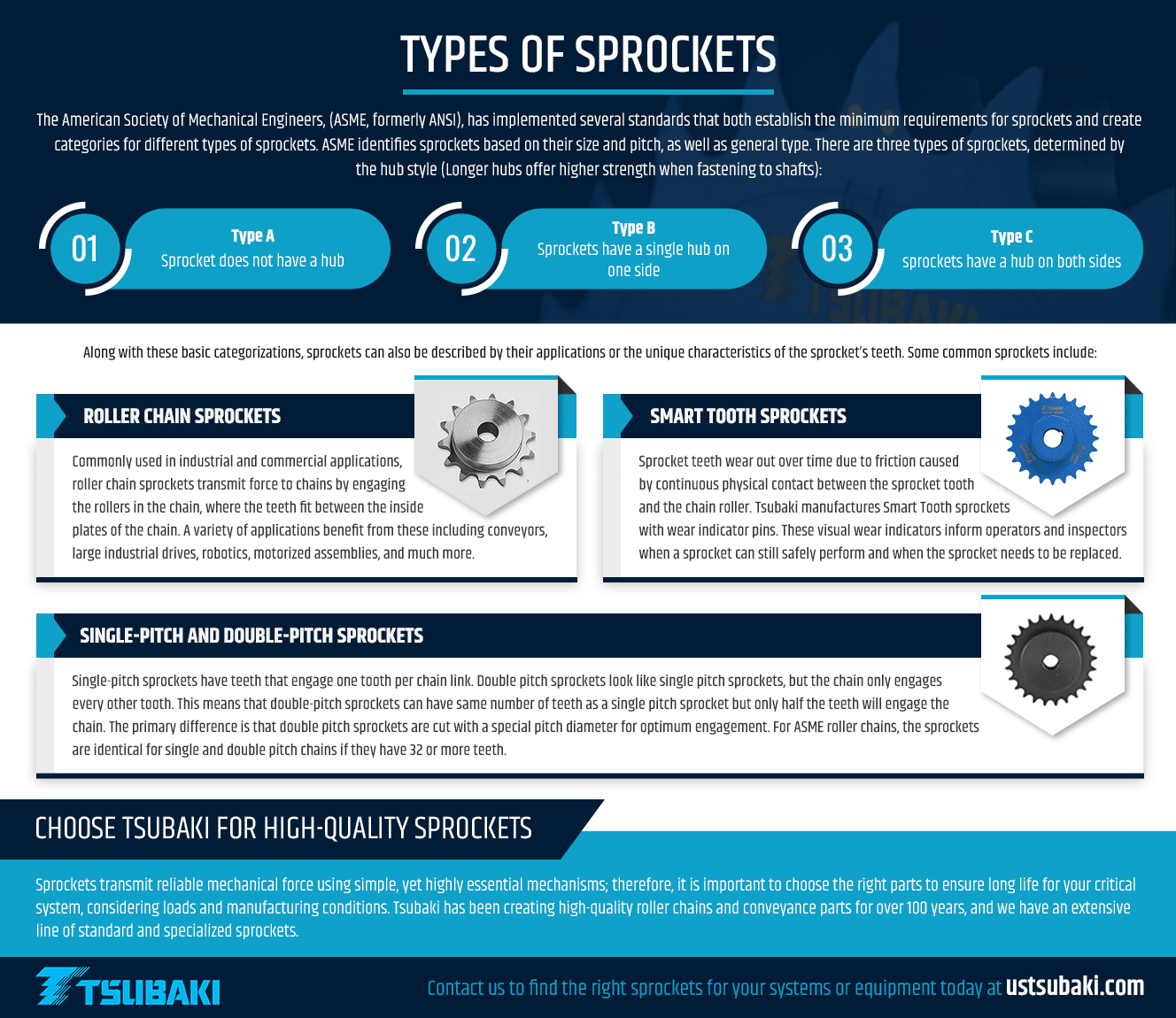

TYPES OF SPROCKETS

The American Society of Mechanical Engineers, (ASME, formerly ANSI), has implemented several standards that both establish the minimum requirements for sprockets and create categories for different types of sprockets. ASME identifies sprockets based on their size and pitch, as well as general type. There are three types of sprockets, determined by the hub style (Longer hubs offer higher strength when fastening to shafts):

- Type A sprocket does not have a hub

- Type B sprockets have a single hub on one side

- Type C sprockets have a hub on both sides

Along with these basic categorizations, sprockets can also be described by their applications or the unique characteristics of the sprocket’s teeth. Some common sprockets include:

ROLLER CHAIN SPROCKETS

Commonly used in industrial and commercial applications, roller chain sprockets transmit force to chains by engaging the rollers in the chain, where the teeth fit between the inside plates of the chain. A variety of applications benefit from these including conveyors, large industrial drives, robotics, motorized assemblies, and much more.

SINGLE-PITCH AND DOUBLE-PITCH SPROCKETS

Single-pitch sprockets have teeth that engage one tooth per chain link. Double pitch sprockets look like single pitch sprockets, but the chain only engages every other tooth. This means that double-pitch sprockets can have same number of teeth as a single pitch sprocket but only half teeth will engage the chain. The primary difference is that double pitch sprockets are cut with a special pitch diameter for optimum engagement. For ASME roller chains, the sprockets are identical for single and double pitch chains if they have 32 or more teeth.

SMART TOOTH SPROCKETS

TSUBAKI OFFERINGS

Along with the four types of sprockets described above—roller chain, single-pitch, double-pitch, and Smart Tooth sprockets—our team specializes in manufacturing other popular sprockets like:

- Drum Sprockets: These sprockets are typically wider to increase the overall surface contact between the sprocket and chain. This reduces the pressure on both parts and creates longer-lasting systems for heavy-duty drag conveyer equipment.

- Steel-Split Sprockets: These sprockets are split in half for easier installation into chain systems that are difficult to access without having to remove the shafts. Operators can position each half within the chain before bolting the two halves together. This allows for replacement of only the sprocket without taking apart the whole assembly and saving operators from having to loosen or reposition the chain.

- Idler Sprockets: Idler sprockets help guide chains in an application and to help long chains from becoming too slack. .

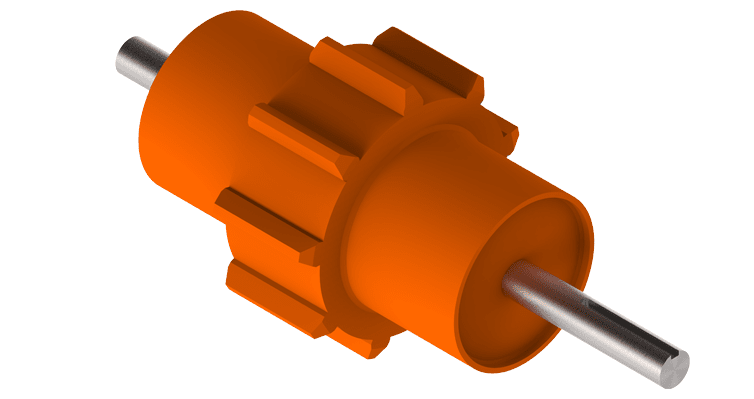

- Bushed Sprockets: Bushed sprockets can simplify the maintenance of chain systems by allowing only the worn out sprocket portion to be replaced while the bushing remains reusable. Bushings also use a tight tapered mating surface that allows higher torque transmission when compared to simpler keyed assemblies. The close mating surface allows better performance in applications with lots of start/stop operations or shock loads.

CHOOSE TSUBAKI FOR HIGH-QUALITY SPROCKETS

Sprockets transmit reliable mechanical force using simple, yet highly essential mechanisms; therefore, it is important to choose the right parts to ensure long life for your critical system, considering loads and manufacturing conditions. Tsubaki has been creating high-quality roller chains and conveyance parts for over 100 years, and we have an extensive line of standard and specialized sprockets. Contact us to find the right sprockets for your systems or equipment today.