Products at a Glance

Quickly compare our range of products with this overview highlighting key features and benefits that set our products apart.

- Corrosion Resistant Nitrocarburized

This process offers significant cost savings and is an alternative option to stainless steel. This process is available in the complete ATRA-FLEX® Coupling line of products.

Benefits:

- Corrosion & Water Resistant to Chemicals & Harsh Environments

- Increased Surface Hardness

- Lower Coefficient of Friction

- Enhanced Surface Lubricity

- Increased rotating fatigue strength and longer insert life

- Excellent Value Added for a Variety of Industries

- Proven in the Field to Prevent Corrosion

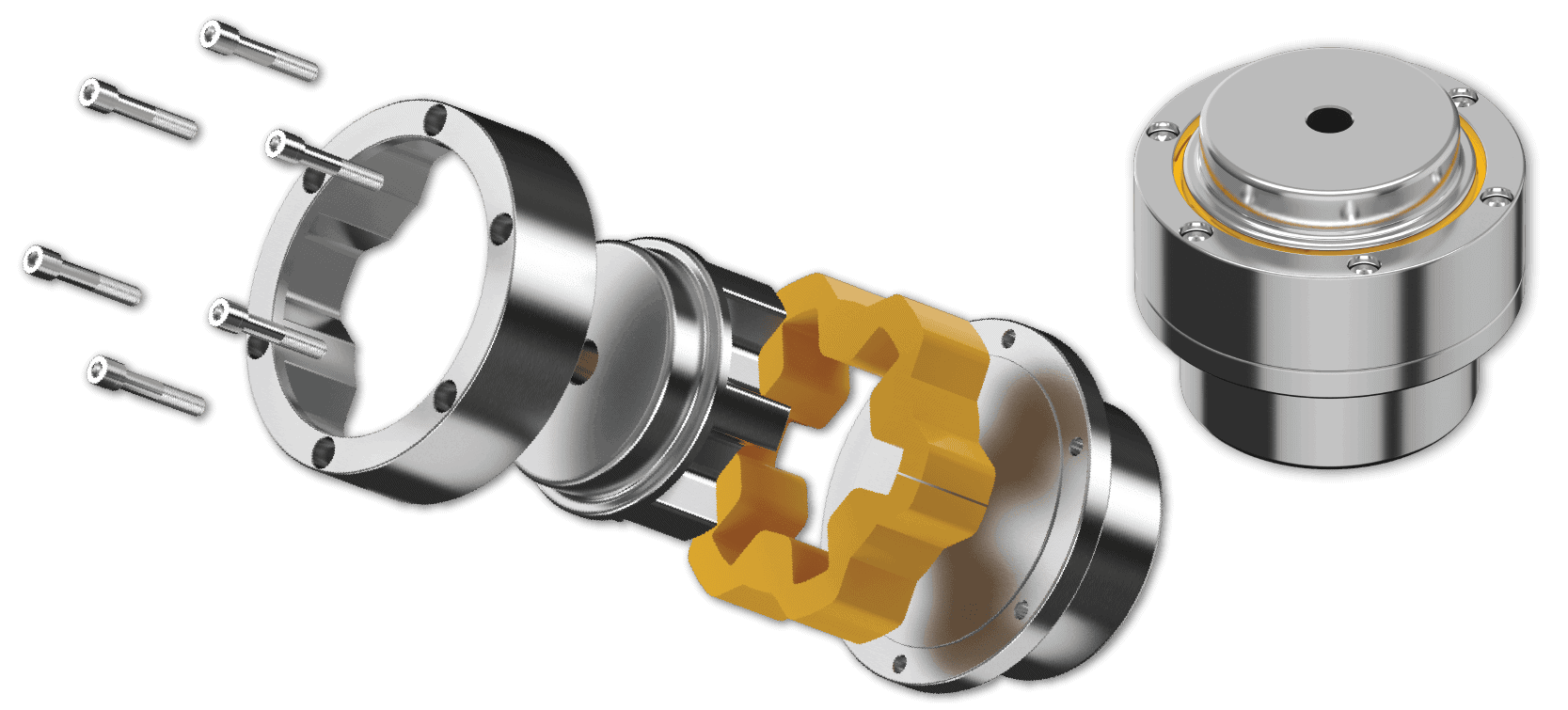

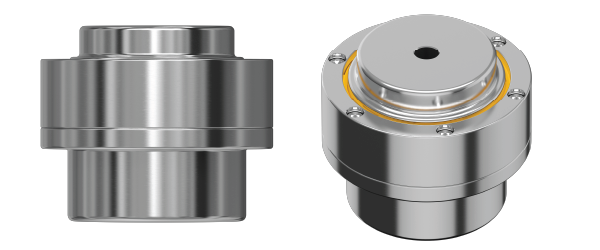

- M-Series Couplings - Quick Look

M-Series is manufactured in the USA. Standard hubs and rings are machined from solid carbon steel rounds and tubing, maintaining tight tolerances which provides excellent coupling balance. Stainless steels in grades 303, 304 and 316 are also available for corrosive environments and food applications.

Benefits:

- Detect and Lock-On Ring Feature

- “Internal Support” of Insert for Higher Horse Power

- Higher Horse Power in a Smaller Package

- Large Bore Capacity

- No Exposed Shaft on Spacer Coupling

- Very Economical

- Torque Ratings up to 3,610,000lbs

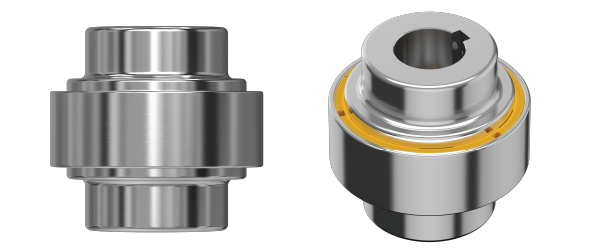

- T-Series Couplings - Quick Look

T-Series is manufactured in the USA. Standard hubs and rings are machined from solid carbon steel rounds and tubing, maintaining tight tolerances which provides excellent coupling balance. Stainless steels in grades 303, 304 and 316 are also available for corrosive environments and food applications.

Benefits:

- Detect and Lock-On Ring Feature

- “Internal Support” of Insert for Higher Horse Power

- Higher Horse Power in a Smaller Package

- Large Bore Capacity

- No Exposed Shaft on Spacer Coupling

- Very Economical

- Torque Ratings up to 3,610,000lbs

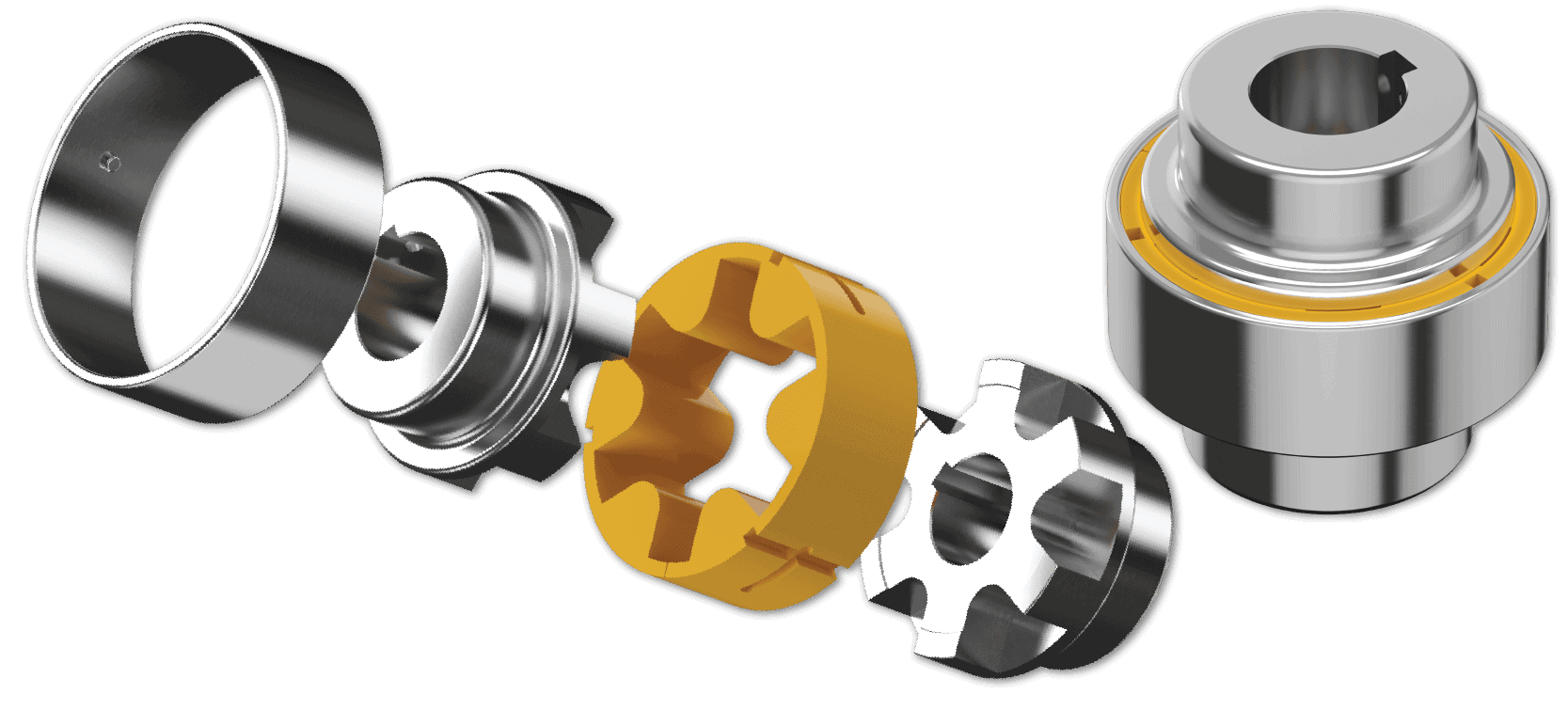

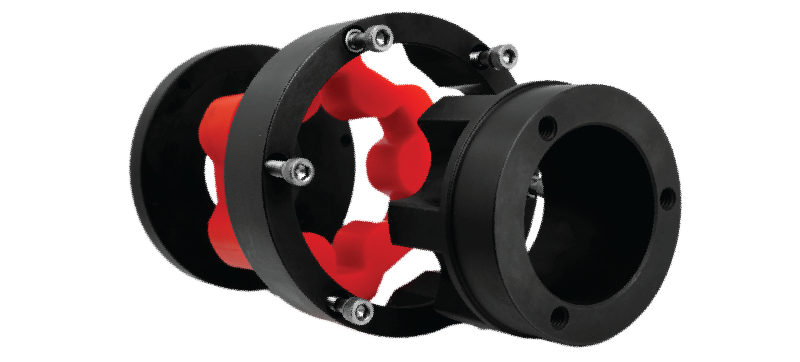

- A-Series Couplings - Quick Look

A-Series is manufactured in the USA. Standard hubs and rings are machined from solid carbon steel rounds and tubing, maintaining tight tolerances which provides excellent coupling balance. Stainless steels in grades 303,304 and 316 are also available for corrosive environments and food applications.

Benefits:

- Detect and Lock-On Ring Feature

- No Lubrication or Service Required

- Easy Replace in Place Insert

- Low Reaction Forces

- Shear Protection

- Torque Ratings up to 570,000 (lb-in)

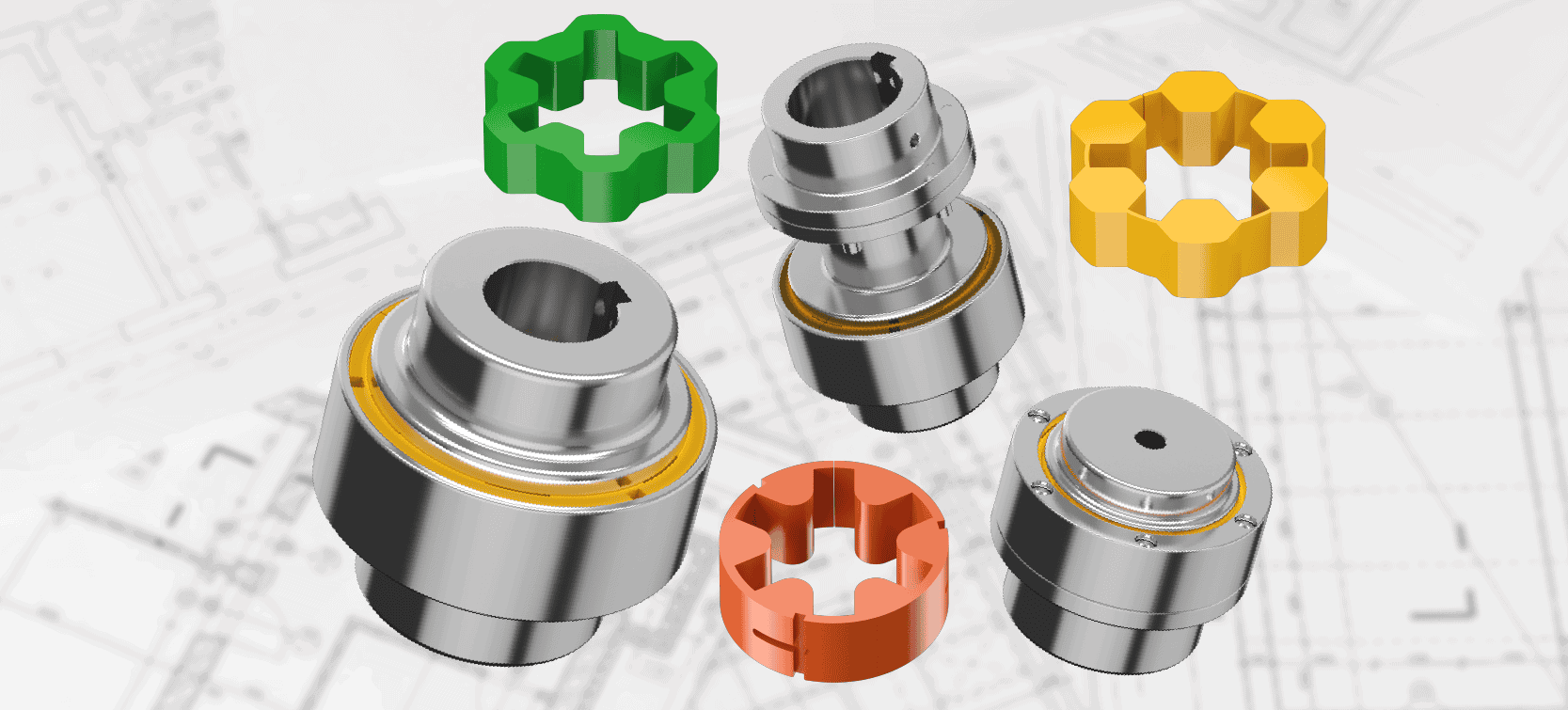

Why Choose ATRA-FLEX Flexible Shaft Couplings?

ATRA-FLEX flexible shaft couplings with elastomeric inserts are manufactured for the Power Transmission Industry and can cover wide variety of applications. They are designed to increase reliability and efficiency. ATRA-FLEX is the smart choice when operations are looking for standardization.

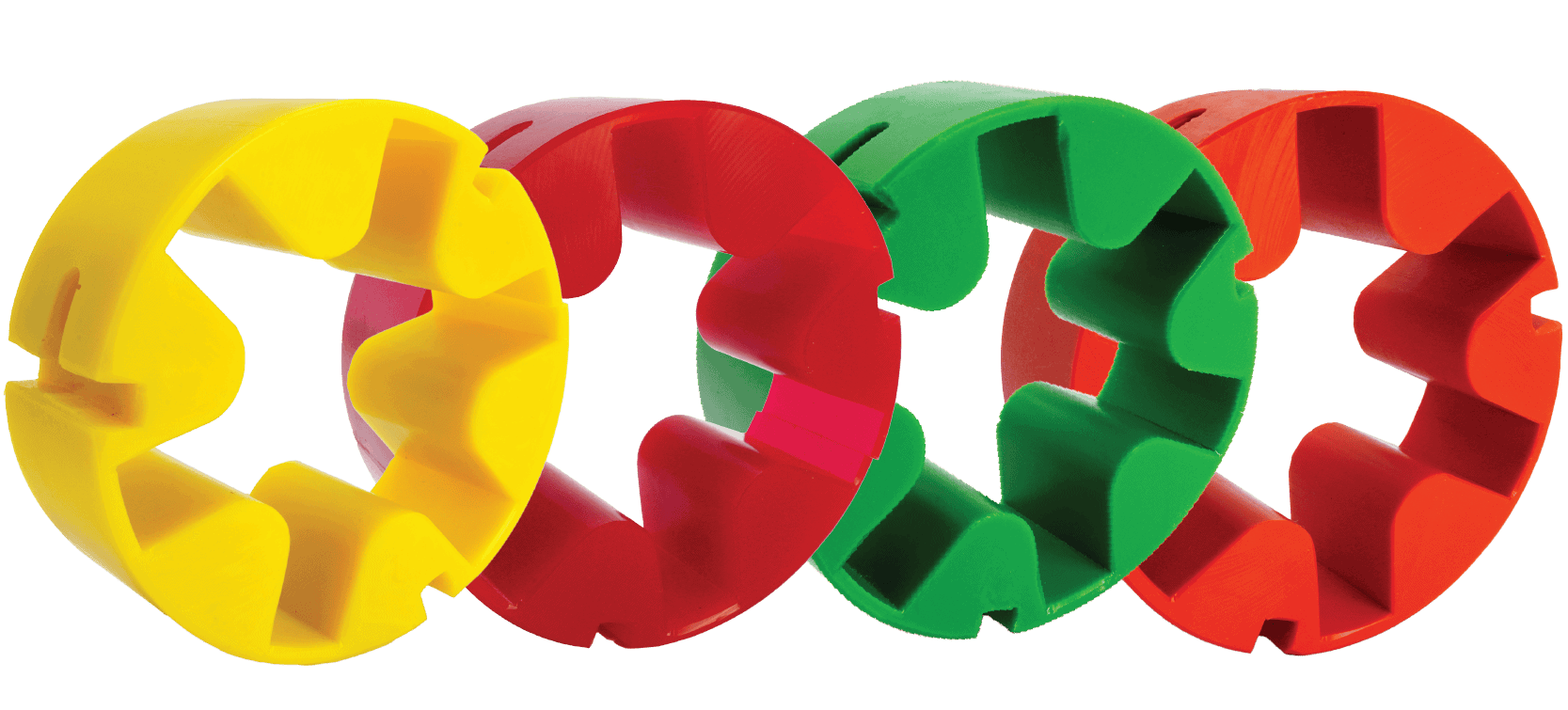

Couplings are available in many coupling styles and have the durability to face the challenges in the harshest of environments. Whether your operation requires standard sizing or needs quick delivery on a custom design, ATRA-FLEX has you covered. They require no lubrication and minimal maintenance. They are easy to install and take minutes to replace the polyurethane insert.

ATRA-FLEX couplings operate without any metal-to-metal contact therefore the elastomeric insert is the only spare part you’ll need. We offer a stainless-steel version for the food industry as well as a cost savings alternative to stainless steel called nitrocarburized that is corrosion resistant and will add lubricity increasing the life of the insert.

Industries

Around the World and in a variety of Industries, customers improve their performance by turning to ATRA-FLEX® Flexible Couplings. Our associates deliver value by working closely with customers to provide management and power transmission solutions that cater to their specific industry and applications.

Common Industries:

- Dredging

- Pulp and Paper Mills

- Oil and Gas

- Mining

- Cement/ Aggregate

- Marine

- Agriculture

- Power Generation

- Pump Systems

- Food Processing

- Steel Industry

Our Commitment

- Outperforms the competition: USA MADE couplings ensure quality manufactured couplings that create more efficiency and reliability

- Accepts misalignment up to 2 degrees.

- Excellent choice for Standardization: Replace or retrofit all styles of couplings in high and low torque applications.

- Reduce Inventory: No metal-to-metal contact allows you to lower your inventory of spare parts to inserts only.

- No lubrication.

- Standard inserts have a temperature range from -60℉ to 250℉ with high temperature inserts available up to 350 °F.

- A variety of inserts are available in a range of hardness to meet most torsional stiffness and torque requirements and offers very high resistance to chemicals and weather.

- Absorbs and dampens torsional vibration shock extending the life of your driven equipment.

- Lower total cost of ownership: Save money and downtime with the ease of replacement of inserts. No need to remove hubs or disassemble the driving or driving equipment.