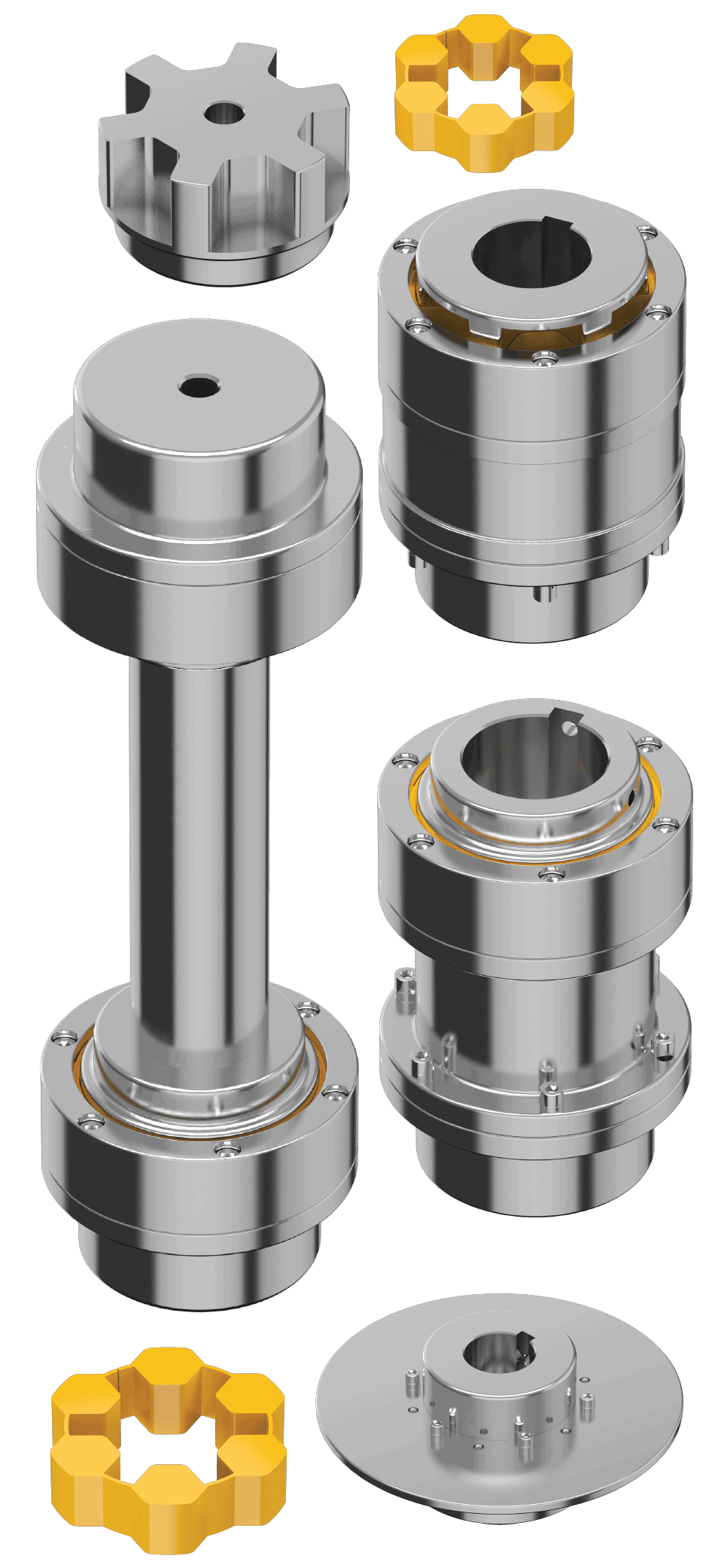

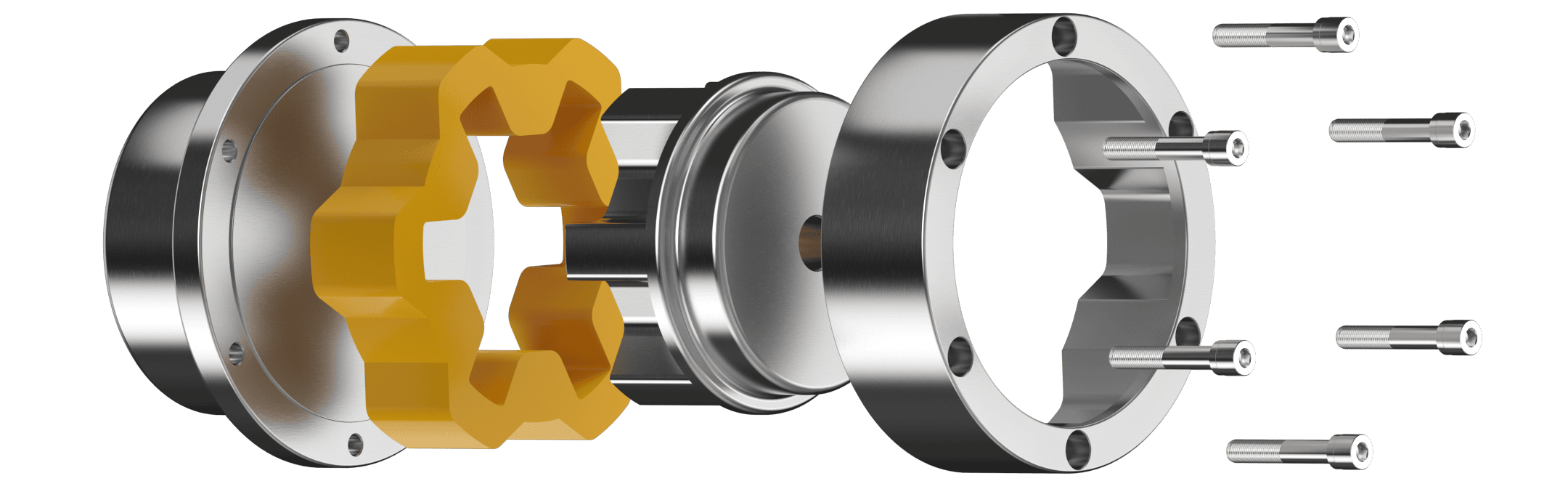

ATRA-FLEX T-Series Couplings

Reduce Cost of Maintenance and Downtime with T-Series Couplings

For reliability and total low cost of ownership, customers turn to ATRA-FLEX flexible couplings. We are proud to provide

high-quality couplings that have been proven to increase efficiency and productivity for industrial applications worldwide since 1980.