With the widest variety of chains on the market, Tsubaki of Canada premium roller chain products include: self-lube LAMBDA® series chain, corrosion-resistant Neptune® chain, fatigue-resistant super chain, and our latest generation of high-quality, long-lasting ANSI chain.

Appropriate for applications as diverse as food packaging, forklift trucks, oilfield mining, and more, our roller chains provide reliable and powerful performance. To learn more, please select a category below.

If you are searching for a straightforward and simple method of transmitting mechanical energy, look no further than roller chains. Roller chains are one of the final connections in motion control systems and are comprised of rollers, pins, side plates and bushings. To work effectively, a sprocket connected to the motor moves the chain, while the other end is connected to the load.

In this section, we’ll discuss how roller chains work, why they are effective, and what types of roller chains we can offer for your project.

Our Roller Chain Lines

HOW DO ROLLER CHAINS WORK?

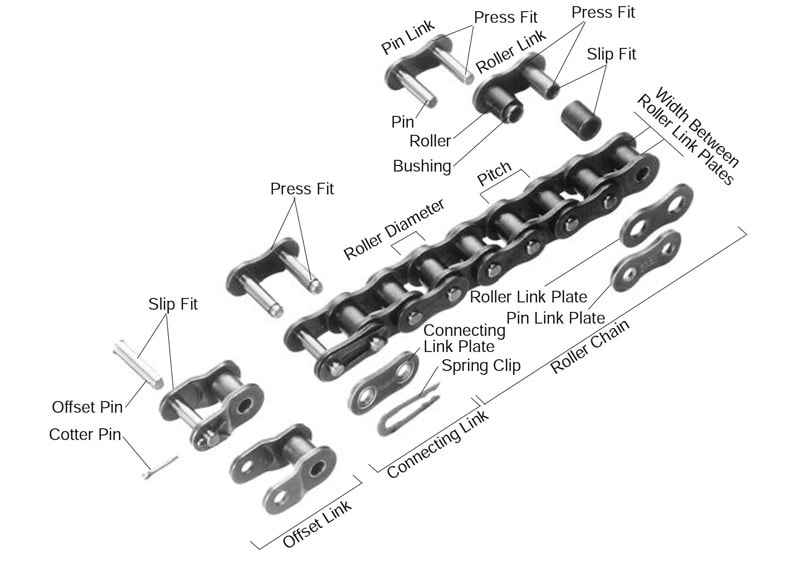

Roller chains run on a rotating sprocket connected to a motor that moves the chain. In most roller chains, two types of links alternate in order for it to work.

- Inner links (also known as Roller Links): two inner plates held together by two sleeves or bushings that sit under two rollers.

- Outer links (also known as Pin Links): two outer plates held together by pins, pass through bushings of inner links.

The environment in which your roller chain is used, along with the work it performs, will influence what type of roller chain to use and how often you’ll need to change the roller chain. Rest assured, roller chains are one of the most effective and efficient options for power transmission and conveyance applications.

You will find roller chains most commonly used for transmission of mechanical power of industrial machinery and for product conveyance throughout manufacturing facilities. Common industries:

- Food & Beverage

- Material Handling & Packaging

- Automotive

- Primary Metals

- Construction

- Mining

TYPES OF ROLLER CHAINS BY TSUBAKI

Tsubaki, the global market share leader for roller chain, manufactures a large variety of roller chains for any application. Some of the chains include:

- ANSI roller chains

- Standard and made-to-order attachment chains

- Lambda® Lube-Free Chains

- Plastic chains

- Titan® harsh environment chains

- British standard chains

- Anti-corrosive/heat resistant chains

- Specialty, made-to-order chains

- Super Stainless™ chain (a unique stainless steel chain with the strength of carbon steel)

- Gripper™ chains (Packaging)

Tsubaki prides itself on manufacturing and properly applying each of the roller chains we make to ensure your specific application is optimized for efficient operation.

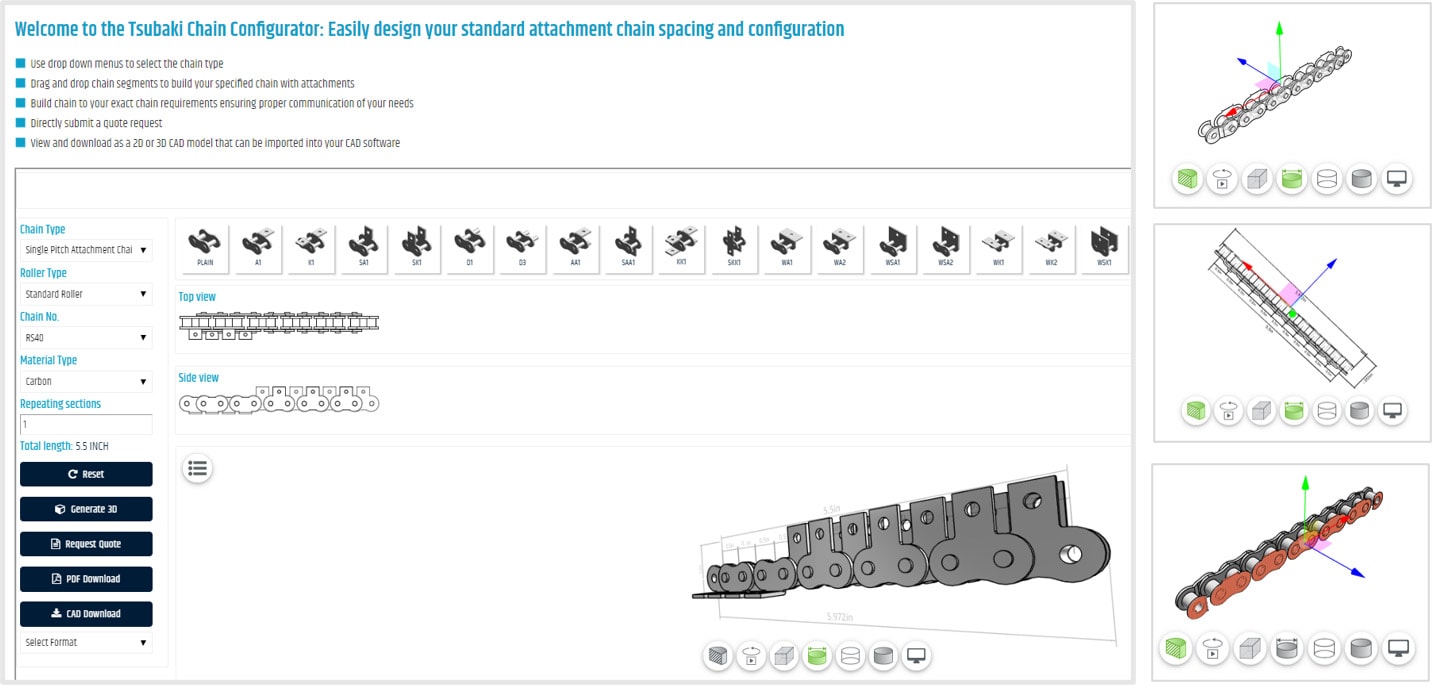

To assist in building the proper attachment chains for your application, and to receive a quote, we have created an on-line attachment chain configurator for designing standard attachment chains with the specific spacing you require. The attachment chain configurator is an easy-to-use, on-line program with the following features: