Tsubaki Zip Chain Actuators® (ZCA) Drive Greater Production Efficiency

Download Tsubaki Zip Chain Actuator Brochure

Common linear actuators – such as electric screw-type, hydraulic and pneumatic – are effective for facilitating pushing and pulling applications but can create unexpected challenges for plant operators.

Hydraulic cylinders, for example, are often used in stacking applications. To create enough space for the cylinder to move, however, you might have to dig a pit to house the actuator body. Hydraulic cylinders can also be limited by low speeds, while oil leaks can lead to ongoing and expensive maintenance issues.

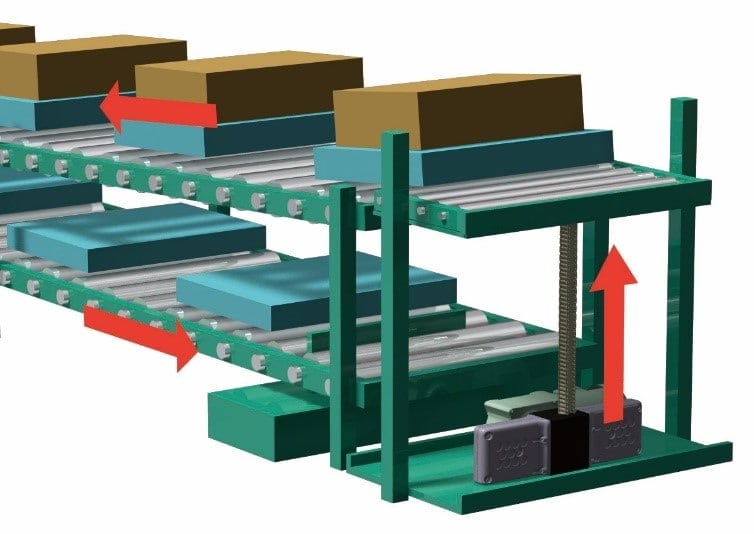

Typically used in horizontal push/pull applications such as conveyors, pneumatic cylinders also require a lot of space to ensure full range of motion. They can protrude into aisles or onto the conveyor, limiting installation options and leading to an inefficient use of space.

To help solve the challenges created by those linear actuators, Tsubaki pioneered a chain technology in which two strands of chain interlock like a zipper, forming a single strong chain for pushing and pulling applications. The Zip Chain Actuator (ZCA)–also called meshing chain, rigid chain, and linear chain– offers several advantages over other linear actuators, including greater space savings, high speed and high accuracy function, and free installation direction.

Here are four ways Zip Chain Actuators can improve and streamline your operations:

1. Increase speed and efficiency

To increase production efficiency, you’ll need to operate with shorter cycle times, even for high lifts. The ZCA can achieve a maximum speed of 1,000mm/sec during high speed operation, which far exceeds the speeds seen in screw-type cylinders and hydraulic or pneumatic cylinders. Servo motors can be installed on the unit to precisely control rotational movement and make the ZCA capable of precise and accurate multi-stop positioning.

Additionally, the ZCA can return energy savings of up to 50 percent compared to hydraulic and pneumatic cylinders because the use of a brake motor allows it to hold loads in place without any need for constant electrical power.

2. Extend wear life for equipment

Linear actuators need to be durable in order to withstand frequent, high-speed operation. To maximize wear life and reduce the cost and man-hours for replacement, it is best to have a device that can withstand both high lifts and long travel distances. The ZCA is the perfect solution, featuring superb wear resistance and low chain elongation, which gives it an expected travel distance of 4,000 km.

3. Create a more compact production line

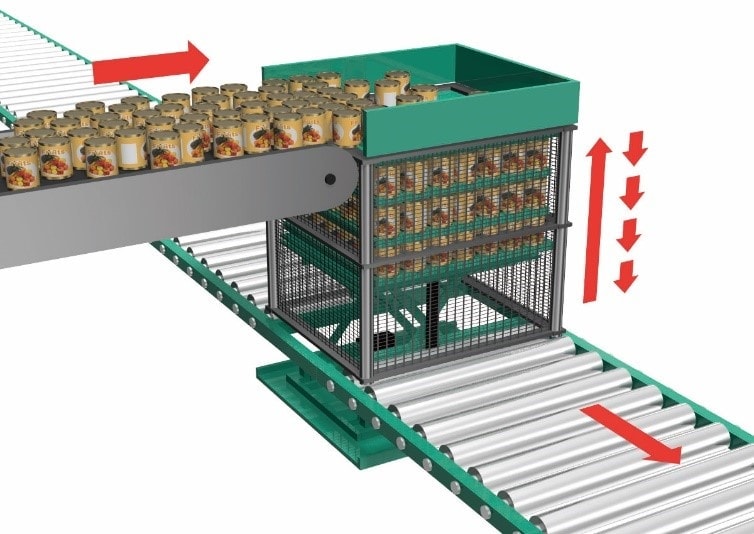

The compact structure of the ZCA enables various installation options—including lifting, horizontal, and suspending installation. The height of the chain case is about 1/10 of the stroke and its integrated drive structure allows the unit to be installed in narrow spaces.

ZCA is ideal for applications where you:

• Need to position low-height equipment without creating a pit below

• Want a device that fits into a small space

• Want to place lifters on transporters

4. Reduce maintenance

Unlike a hydraulic actuator, the ZCA uses grease for lubrication, eliminating the risk of oil leakages due to faulty units and leaking lines. Additionally, the ZCA does not require pneumatic/hydraulic lines as it is connected solely through the use of cables, further reducing the number of parts requiring repair and maintenance.

Zip Chain Actuators are the latest material handling solution in a long line of linear motion products designed and developed by Tsubaki. Learn more about how to use Zip Chain Actuators in your applications or contact us today to request specific information from our team.