What is a Torque Limiter?

Critical drive components can fail or fracture from just a single moment or action. This incidence, called mechanical overload, is when a rotating component experiences torques beyond what the system is designed to handle. Any rotating operation can develop a lot of torque and, if there is any kind of malfunction, all of that force can break affected components including, but not limited to, the couplings, the drive or motor shafts, and/or the gearing.

Mechanical overload protection devices like the Tsubaki Torque Limiter can help reduce the risk of critical component failure.

Simply put, these devices protect rotating components from the risk of mechanical overload. Clutches, brakes, and Torque Limiters all fall under this classification. Torque Limiters, specifically, work by slipping during torque overload to prevent driven components from experiencing excessive torque loads. If a torque overload occurs, the Torque Limiter is able to protect critical equipment by disconnecting the driving shaft from the driven components.

How Does a Torque Limiter Work?

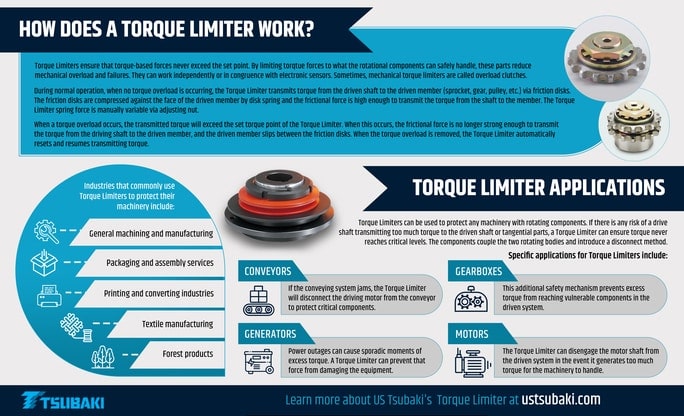

Torque Limiters ensure that torque-based forces never exceed the set point. By limiting torque forces to what the rotational components can safely handle, these parts reduce mechanical overload and failures. They can work independently or in congruence with electronic sensors. Sometimes, mechanical torque limiters are called overload clutches.

During normal operation, when no torque overload is occurring, the Torque Limiter transmits torque from the driven shaft to the driven member (sprocket, gear, pulley, etc.) via friction disks. The friction disks are compressed against the face of the driven member by disk spring and the frictional force is high enough to transmit the torque from the shaft to the member. The Torque Limiter spring force is manually variable via adjusting nut.

When a torque overload occurs, the transmitted torque will exceed the set torque point of the Torque Limiter. When this occurs, the frictional force is no longer strong enough to transmit the torque from the driving shaft to the driven member, and the driven member slips between the friction disks. When the torque overload is removed, the Torque Limiter automatically resets and resumes transmitting torque.

Torque Limiter Applications

Torque Limiters can be used to protect any machinery with rotating components. If there is any risk of a drive shaft transmitting too much torque to the driven shaft or tangential parts, a Torque Limiter can ensure torque never reaches critical levels. The components couple the two rotating bodies and introduce a disconnect method.

Industries that commonly use Torque Limiters to protect their machinery include:

- General machining and manufacturing

- Packaging and assembly services

- Printing and converting industries

- Textile manufacturing

- Forest products

Specific applications for Torque Limiters include:

- Conveyors: If the conveying system jams, the Torque Limiter will disconnect the driving motor from the conveyor to protect critical components.

- Gearboxes: This additional safety mechanism prevents excess torque from reaching vulnerable components in the driven system.

- Generators: Power outages can cause sporadic moments of excess torque. A Torque Limiter can prevent that force from damaging the equipment.

- Motors: The Torque Limiter can disengage the motor shaft from the driven system in the event it generates too much torque for the machinery to handle.

Torque Limiter Sprockets by Tsubaki

Our Torque Limiters offer excellent protection from excessive torque and the risks of mechanical overload. Tsubaki now offers a factory pre-assembled Torque Limiter Sprocket to help further improve our customer experience.

Tsubaki also produces the following overload protectors:

- Shock Guard®

- Mini Keeper

- Torque Keeper

- Shock Relay

- Shock Monitor

Browse our wide selection of mechanical protection devices and Torque Limiters here. You can also contact us today to request specific information from our team.