All About Zip Chain Actuators®

Zip Chain Actuators—also commonly referred to as meshing chains, rigid chains, linear chains, and push-pull chains—are used alongside other material handling equipment to facilitate push and pull applications. These actuating units consist of two chains that interlock like a zipper to form a rigid column and are available with a wide range of features and performance characteristics to suit different applications. Typical uses range from motorized opening and closing of windows in buildings to heavy-duty industrial applications like platform lift operators and automated assembly lines.

How Do Zip Chain Actuators Work?

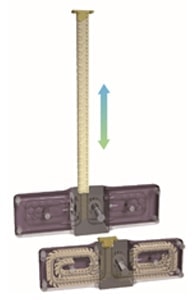

Zip Chain Actuators (ZCA) have a motor-driven shaft which turns a specially designed sprocket that converts the motor’s rotation into linear motion. When the motor rotates in one direction, it zips the ZCA segments and locks the chains’ links to form a straight, rigid chain; when the motor rotates in the other direction, the sprocket disengages the links and the chain retracts and coils back into a compact housing.

Zip Chain Actuator System Performance

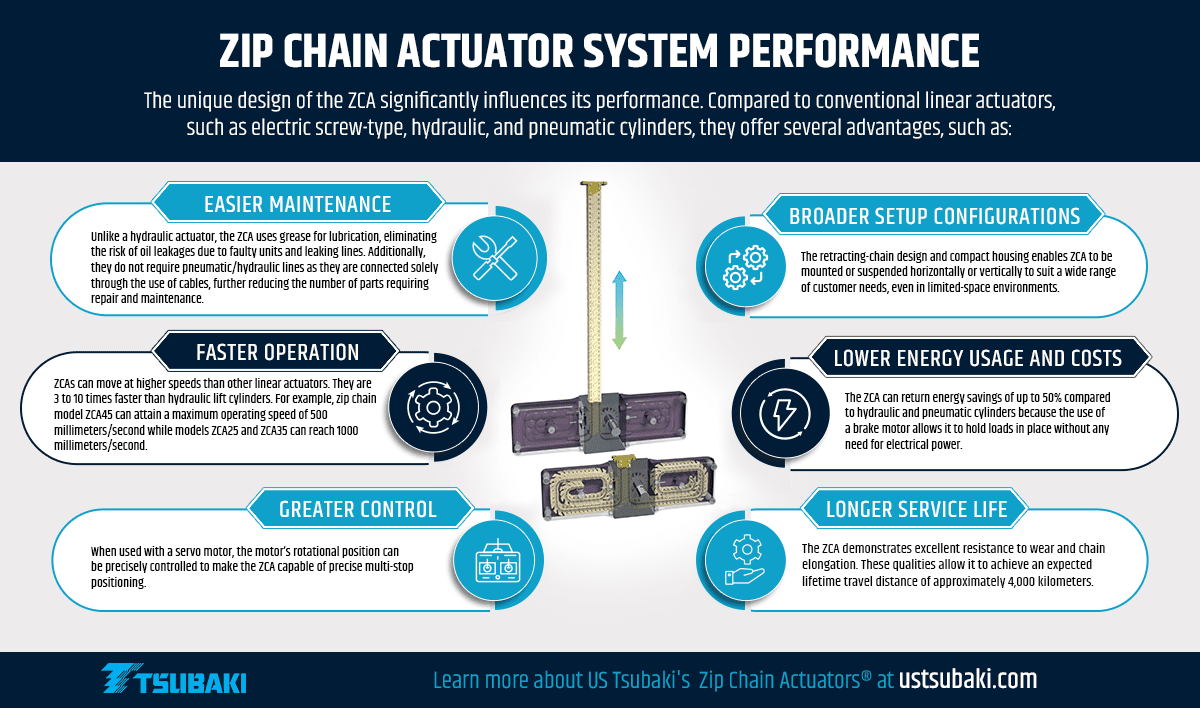

The unique design of the ZCA significantly influences its performance. Compared to conventional linear actuators, such as electric screw-type, hydraulic, and pneumatic cylinders, they offer several advantages, such as:

- Easier maintenance. Unlike a hydraulic actuator, the ZCA uses grease for lubrication, eliminating the risk of oil leakages due to faulty units and leaking lines. Additionally, they do not require pneumatic/hydraulic lines as they are connected solely through the use of cables, further reducing the number of parts requiring repair and maintenance.

- Faster operation. ZCAs can move at higher speeds than other linear actuators. They are 3 to 10 times faster than hydraulic lift cylinders. For example, zip chain model ZCA45 can attain a maximum operating speed of 500 millimeters/second while models ZCA25 and ZCA35 can reach 1000 millimeters/second.

- Greater control. When used with a servo motor, the motor’s rotational position can be precisely controlled to make the ZCA capable of precise multi-stop positioning.

- Broader setup configurations. The retracting-chain design and compact housing enables ZCA to be mounted or suspended horizontally or vertically to suit a wide range of customer needs, even in limited-space environments.

- Lower energy usage and costs. The ZCA can return energy savings of up to 50% compared to hydraulic and pneumatic cylinders because the use of a brake motor allows it to hold loads in place without any need for electrical power.

- Longer service life. The ZCA demonstrates excellent resistance to wear and chain elongation. These qualities allow it to achieve an expected lifetime travel distance of approximately 4,000 kilometers.

Zip Chain Product Options

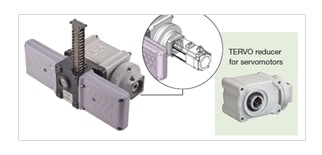

Zip Chain Actuators are available with a hypoid motor or Tsubaki TERVO reducer for servo motors.

- A ZCA with a hypoid gear motor is available in every size to accommodate a wide range of customer requirements. With fewer components, this ZCA facilitates an easier assembly and selection and all fits in a compact, integrated footprint.

- A ZCA with a Tsubaki TERVO reducer for servo motors is a compact solution that provides more precise high-speed positioning and unlimited cycling frequency.

Zip Chain Actuator Applications

As mentioned above, the design of a ZCA makes it suitable for operating at high speeds and frequencies with precise multi-stop positioning and freedom of direction of installation. They are widely used for stacking and unstacking materials, horizontal and vertical push/pull operations, and high-speed sorting applications.

Stacking and Unstacking Materials

The typical operating characteristics of zip chains used in stacking and unstacking operations are:

- Lifting weight: 204 kilograms for stacking and unstacking

- Lifting speed: 30 meters/minute for stacking and unstacking

- Stroke: 1,000 millimeters for both stacking and unstacking

Horizontal or Vertical Push/Pull

Horizontal and vertical zip chains for push/pull applications can utilize servo motors to aid their operations. Both types may offer the following operating characteristics:

- Lifting weight: 102 kilograms

- Lifting speed: 60 meters/minute

- Stroke: 1000 millimeters and 1 second/cycle

High-Speed Sorting

High-speed sorting zip chains may have the following:

- Lifting weight: 102 kilograms

- Lifting speed: 60 meters/minute

- Stroke: 750 millimeters

Quality Zip Chain Actuators From Tsubaki

Since its founding in Japan in 1917, Tsubakimoto Chain Company (Tsubaki) has designed, manufactured, and supported many types of bulk material handling equipment. Zip Chain Actuators are the latest material handling solution in a long line of linear motion products designed and developed by Tsubaki.

At Tsubaki, we strive to offer the highest level of quality products and services for optimizing plant operations. From clutches & backstops, to power cylinders, to sprockets, to Zip Chain Actuators, Tsubaki offers a wide range of high-quality power transmission and motion control products. Learn more about Zip Chain Actuators and our other products by contacting us today.