Guide to Overload Protection Relays

Electric motors see wide usage in machines with rotating components. Motors are often quite expensive, so it is important to prevent them from failure caused by carrying more electric current than their rated amperage. Electrical overload can sometimes develop from ground faults (short-circuits in the motor windings or peripheral cables), but more commonly occurs due to jamming or improper operation.

Overload protection relays prevent motor damage by monitoring the current in the motor circuit and breaking the circuit when an electrical overload or a phase failure is detected. Since relays are much cheaper than motors, they provide an affordable way of protecting motors.

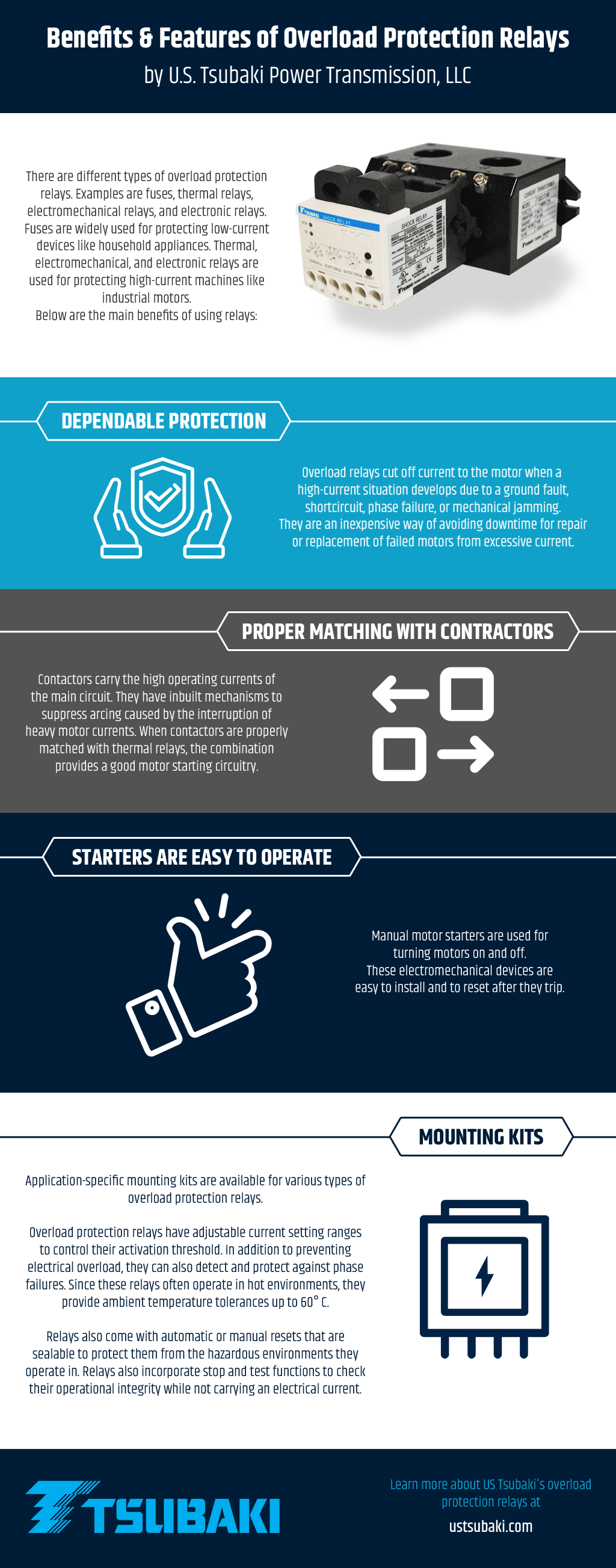

Benefits and Features of Overload Protection Relays

There are different types of overload protection relays. Examples are fuses, thermal relays, electromechanical relays, and electronic relays. Fuses are widely used for protecting low-current devices like household appliances. Thermal, electromechanical, and electronic relays are used for protecting high-current machines like industrial motors. The main benefits of using relays are:

Dependable Protection

Overload relays cut off current to the motor when a high-current situation develops due to a ground fault, short circuit, phase failure, or mechanical jamming. They are an inexpensive way of avoiding downtime for repair or replacement of failed motors from excessive current.

Proper Matching with Contractors

Contractors carry the high operating currents of the main circuit. They have inbuilt mechanisms to suppress arcing caused by the interruption of heavy motor currents. When contactors are properly matched with thermal relays, the combination provides a good motor starting circuitry.

Starters are Easy to Operate

Manual motor starters are used for turning motors on and off. These electromechanical devices are easy to install and to reset after they trip.

Mounting Kits

Application-specific mounting kits are available for various types of overload protection relays.

Overload protection relays have adjustable current setting ranges to control their activation threshold. In addition to preventing electrical overload, they can also detect and protect against phase failures. Since these relays often operate in hot environments, they provide ambient temperature tolerances up to 60° C.

Relays also come with automatic or manual resets that are sealable to protect them from the hazardous environments they operate in. Relays also incorporate stop and test functions to check their operational integrity while not carrying an electrical current.

View Our Catalog of Overload Protection Devices

Overload Protection Relay Product Considerations

Overload protection relays protect against the following fault situations:

Current Overload

Motor coils degrade when they carry currents greater than their designed limit and burn out after prolonged exposure. When currents go above set limits, the overload protection relay trips to avoid damage.

Phase Loss

This is an important fault category since it is the leading cause of motor failures. It is caused when one of the phases of the electrical supply to the motor fails.

Others

This miscellaneous category covers a variety of situations like ground faults, stalling or jammed motors, load imbalances (including under load), and voltage fluctuations.

Overload Protection Relay Products by Tsubaki

Tsubaki offers the following devices to protect against surges in electrical currents or torques:

- Electronic Shock Relays: These relays protect against surges in electrical currents—under loads as well as overloads. Using them will prevent downtimes from unanticipated failures and expensive repairs. They help to keep your overall maintenance costs low.

- Mechanical Shock Guards: These mechanical relays protect against surges in mechanical torque. Torque surges can occur in dusty, humid, and high-temperature environments. These devices disengage when the torque exceeds the threshold value and will reengage when the torque surge disappears.

Tsubaki of Canada is a leading manufacturer and supplier of motion control and power transmission products and is a subsidiary of the Tsubakimoto Chain Company, headquartered in Japan. With over 100 years of manufacturing experience, Tsubaki prides itself on excellence in quality, reliability, and customer service and strives to be the manufacturer who provides the best overall value to customers.

Contact us for all your overload protection relay requirements.